Slow welding refers to the welding rate of stainless steel, and the company requires high production efficiency in the production line. Traditional welding is prone to a decrease in work efficiency over time, affecting welding efficiency. Welding robots can complete long-term welding and perform repeated welding actions during welding, effectively improving the production efficiency of the production line.

The most important factor in welding is the heavy responsibility of welding. In the production of stainless steel welding, the heavy responsibility of welding causes high labor intensity for workers, which can easily lead to occupational diseases during welding and cause property losses to the company. Welding robots can automate the welding process, freeing workers from the heavy responsibility of welding and preventing the occurrence of occupational diseases.

Welding cost refers to the customer's welding cost. The welding cost mentioned by the editor mainly includes labor cost and material cost. The cost of welding robots is equivalent to the annual salary of an ordinary welder. In welding, they can manipulate the distribution of welding materials without excessive consumption of welding materials, saving the company's production cost.

1.5 ton handling robot

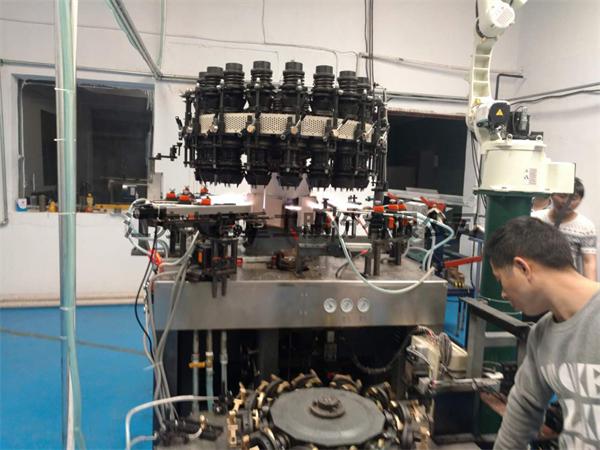

Automatic guide wheel gripping and assembly system

Robot handling glass tubes